Food and drink giant PepsiCo is piloting AI-driven digital twins to redesign factories and warehouses, lifting throughput and cutting investment costs.

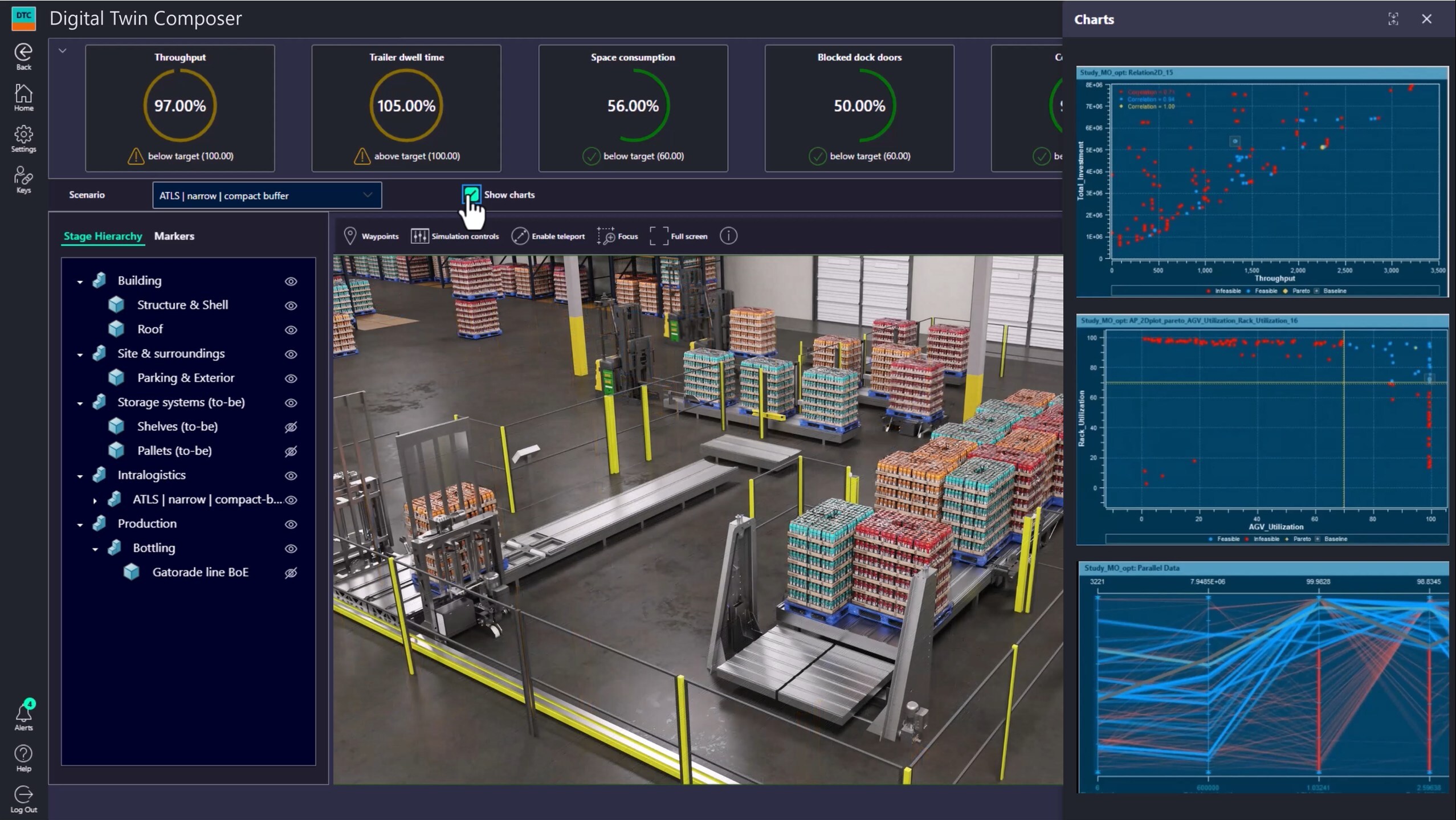

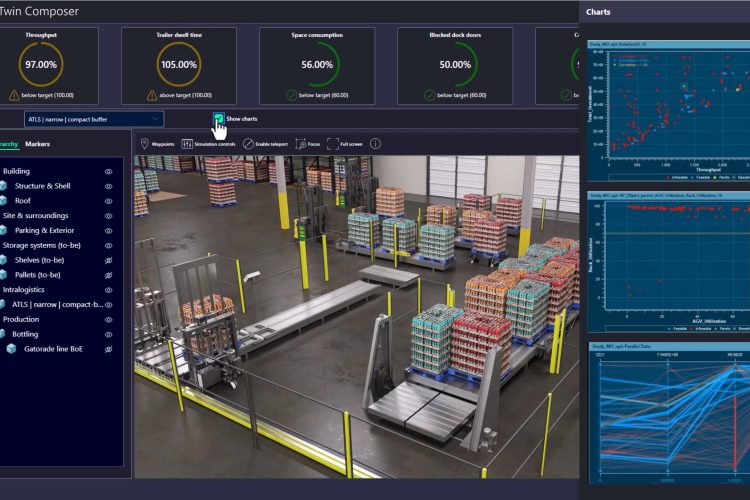

Image Credit: PepsiCo

PepsiCo has begun rolling out AI-powered digital twins across its supply chain under a multi-year partnership with Siemens and NVIDIA, in what it describes as an industry-first move for a global consumer packaged goods business.

The collaboration was announced at CES 2026 in Las Vegas and centres on digitally simulating manufacturing plants and warehouse operations before any physical changes are made. Early pilots are already under way at selected US sites, with plans to scale the approach globally.

At pilot locations, PepsiCo said the use of digital twins has already delivered a reported 20 percent increase in throughput, alongside near-100 percent design validation and capital expenditure reductions of 10–15 percent by uncovering hidden capacity in a virtual environment.

The move comes as food and drink manufacturers face increasing pressure to raise production and distribution capacity while avoiding the cost and disruption of traditional factory expansion. PepsiCo said conventional approaches are too slow and limit flexibility at a time of rising demand and faster product innovation cycles.

Ramon Laguarta, Chairman and CEO of PepsiCo, said:

The scale and complexity of PepsiCo’s business, from farm to shelf, is massive – and we are embedding AI throughout our operations to better meet the increasing demands of our consumers and customers.

Our work with Siemens and NVIDIA will help accelerate our continued journey of becoming a future-fit company, operating with agility and foresight.”

Digital-first planning replaces traditional factory expansion

Rather than investing primarily in new facilities, PepsiCo is shifting to a digital-first planning strategy. The business is using physics-based digital twins and AI agents as co-designers to simulate, validate and optimise facility layouts and supply chain flows before committing capital. This work is being carried out using Siemens’ Digital Twin Composer, built on NVIDIA Omniverse libraries.

Jensen Huang, founder and CEO of NVIDIA, commented:

Physical industries are entering the age of AI. For companies with real-world assets, digital twins are the foundation of their AI journey.

Working with NVIDIA and Siemens, PepsiCo is re-architecting its operations – using physically accurate digital twins and AI to reinvent how it designs, optimises, and runs its global operations.”

Roland Busch, CEO of Siemens AG, added:

We are proud to partner with PepsiCo and NVIDIA to digitally transform their manufacturing facilities using physics-based digital twins and AI from design to engineering to operations.

This collaboration sets a new standard for all industries.”

From virtual models to real-world performance

At pilot sites, PepsiCo has converted factories and warehouses into high-fidelity 3D digital twins that simulate plant operations and the end-to-end supply chain. The models establish a baseline view of performance and allow teams to test alternative configurations virtually.

By recreating every machine, conveyor, pallet route and operator path with physics-level accuracy, AI agents can stress-test layouts and workflows, identifying up to 90 percent of potential issues during virtual optimisation. PepsiCo said teams optimised and validated new configurations within weeks.

Athina Kanioura, CEO, Latin America, and Global Chief Strategy and Transformation Officer of PepsiCo, concluded:

We are deploying the first digital blueprint that reimagines how the supply chain is designed, built, and scaled, a first for the industry.

With a unified, AI-powered digital foundation, PepsiCo is building toward a world where every plant and warehouse operates as part of a single, intelligent ecosystem.”

купить дайсон в москве оригинал dn-fen-kupit-1.ru .

пылесос dyson v15 absolute купить pylesos-dn-1.ru .

пылесос dyson v15 купить pylesos-dn.ru .