Scientists in Singapore have developed two natural processing techniques that significantly improve carob flavour, offering manufacturers a climate-resilient alternative to cocoa.

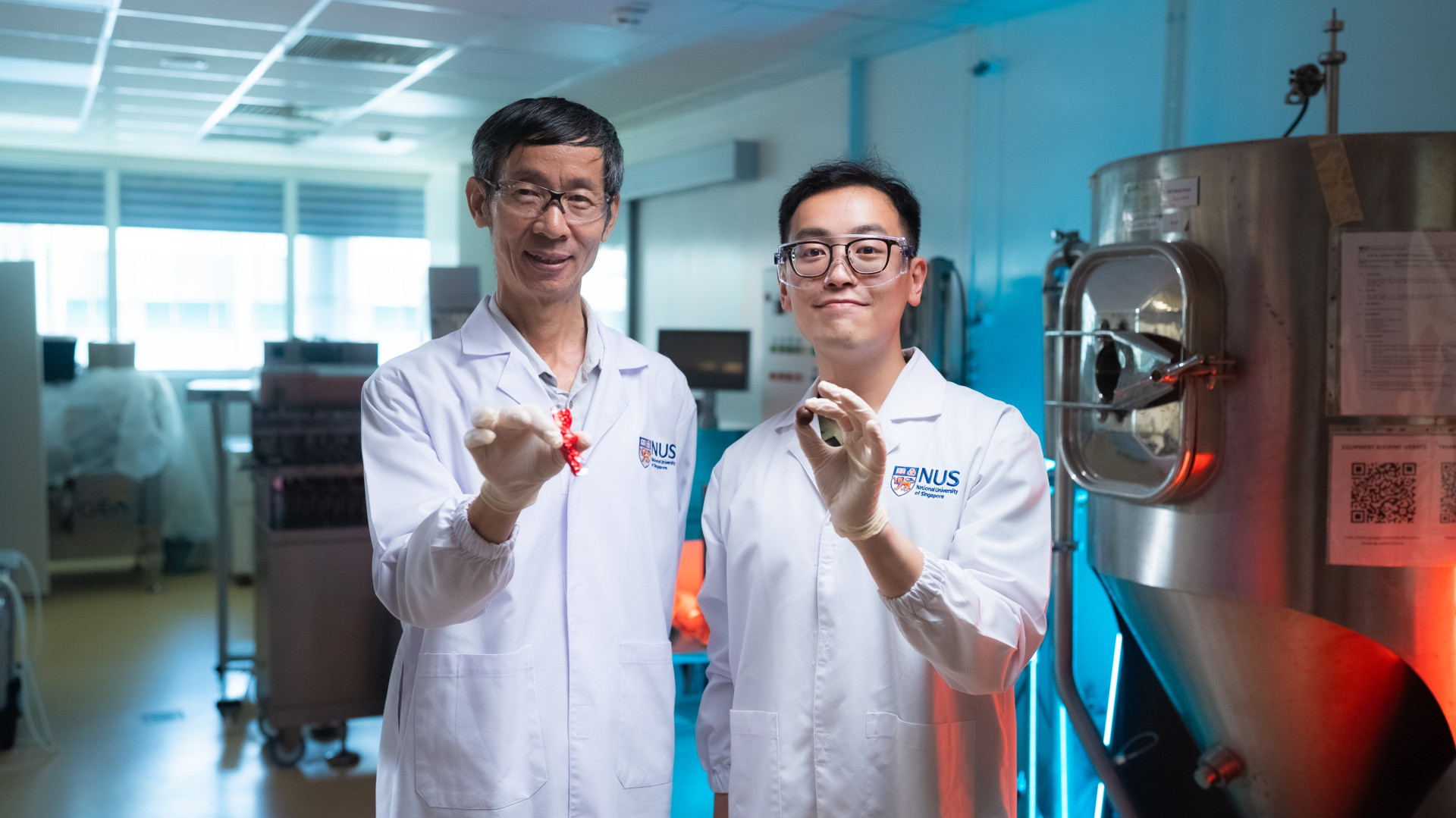

Associate Professor Liu Shao Quan (left) and Mr Manfred Ku from the NUS Department of Food Science and Technology developed novel methods to improve the taste of carob-based chocolate alternatives. Credit: NUS Faculty of Science

Global cocoa supply risks are accelerating interest in sustainable substitutes, and researchers at the National University of Singapore (NUS) say carob could soon offer a viable replacement. A team from the Department of Food Science and Technology at NUS has developed novel, additive-free methods to enhance carob’s flavour so it more closely resembles cocoa while maintaining a clean ingredients list.

Carob pulp, harvested from the hardy Mediterranean tree Ceratonia siliqua, is naturally drought-tolerant and far more climate-resilient than Theobroma cacao, the crop behind conventional chocolate.

With climate change and crop disease threatening global cocoa output, the researchers believe carob could help stabilise confectionery supply chains. Carob also contains natural sugars, removing the need for sweeteners, is caffeine-free and is rich in d-pinitol, a compound linked to anti-diabetic effects.

Led by Associate Professor Liu Shao Quan, the group set out to overcome carob’s long-standing sensory limitations. Liu explained:

Our carob-based innovation meets the relatively untapped and nascent market of alternative chocolate sources. Additionally, our new techniques improve the taste of carob itself, without the use of additives such as flavourings. So, consumers can have the best of both worlds – better flavour and a simple ingredients list.

With these innovations, we aim to make a meaningful contribution towards addressing the current challenges and needs of the chocolate industry.”

Novel processing methods unlock richer cocoa-like flavour

Although roasted carob releases an aroma reminiscent of cocoa, its flavour lacks the bitterness and depth expected by chocolate consumers. These shortcomings have historically prevented carob from being used widely beyond niche health markets.

The NUS team has now published two complementary processing approaches using readily available food-grade enzymes to elevate carob’s flavour during roasting.

The first approach applies enzyme-treated soy protein to roasted carob pulp. This increases amino acids and peptide levels, enhancing bitterness and producing richer cocoa-like notes. The work, published in the Journal of Food Science, focuses on stimulating formation of two core chocolate flavour molecules – 2-methylbutanal and 3-methylbutanal. According to the researchers, the reaction not only adds desirable depth, but also reduces intrinsic off-odours, resulting in what they describe as a smoother, more familiar chocolate-style taste.

The second method, published in Food Chemistry, enhances natural sweetness by encouraging the generation of simple sugars before roasting. These sugars undergo Maillard reactions, creating oxygenated-heterocycles associated with sweet, caramel-like, roasted aromas.

Both treatments use established industrial enzymes, offering scalability and avoiding processes reliant on harsh reagents such as hydrochloric acid. The researchers stress that the methods alter carob’s flavour precursors rather than masking its taste with external additives.

Manfred Ku, first author of the published papers and a PhD researcher at NUS, said the work goes beyond imitation. He added:

Our research is not just about replicating the flavour of cocoa – it’s about diversifying the ingredients we use to make chocolate alternatives. By turning to hardy, climate-resilient crops like carob, we can help the industry adapt to environmental challenges while giving consumers a product they will enjoy.”

Commercial and sustainability benefits for food manufacturers

Carob pulp is currently a low-value by-product of locust bean gum manufacturing, making it an attractive ingredient from both an economic and sustainability perspective. Better utilisation could reduce industrial waste streams while creating new ingredient value for manufacturers. If adopted commercially, confectioners could use the enhanced carob in bars, powdered drinks, spreads and other cocoa-based products, thereby easing reliance on vulnerable cocoa sourcing regions.

The researchers argue that broader carob uptake could help safeguard chocolate supply amid ongoing concerns about land availability, labour issues and disease-related production losses in major West African cocoa regions. Beyond resilience, the ability to produce chocolate alternatives with fewer ingredients aligns with ongoing reformulation efforts across international food categories.

With the taste barrier now significantly reduced, the team is seeking commercial partners. They plan to license the processes or co-develop ventures to scale production and adapt the techniques for different product applications. Further research will examine how roasting parameters can be fine-tuned to deliver specific sensory profiles or introduce novel flavour notes targeted at different consumer markets.

Related topics

Clean Label, Environment, Flavours & colours, Food Security, Ingredients, Lab techniques, Natural, New product development (NPD), Product Development, Research & development, Sensory technology, Supply chain, Sustainability, World Food

Great breakdown! It’s refreshing to see such a well-organized look at virtual sports betting algorithms. For those diving deeper into AI-driven tools, checking out AI Translation can be a game-changer in understanding global trends and tech advancements.

**mitolyn reviews**

Mitolyn is a carefully developed, plant-based formula created to help support metabolic efficiency and encourage healthy, lasting weight management.